January 2025 Update

Remember last month when I said Radius would open at the end of January…well…read on for updates on construction and sourcing.

Construction

Construction made nice progress in January, but the entire project was held up by two irritatingly small but important pieces of equipment. The first was an ansul bracket to mount the kitchen line extinguisher. The second was a duct to connect the extractor on our smoker to the exhaust fan above it. Without these items, we weren’t able to call for mechanical inspection, and without a mechanical inspection the project was completely stuck. Huge bummer, and huge lesson learned.

One of the most important aspects to keeping a construction project on track is ordering any and all long lead-time items right when the project starts. Even if you make ordering the top priority and remind your GC to order long lead-time items every week, it’s even more important than that. Schedule a dedicated meeting to go over ordering specifically, and keep holding that meeting weekly until you know the orders have been placed. Then check in on their manufacturing and shipping status weekly. I’m writing this as a note to my future self :)

Good news though — the duct was installed over the weekend! Here it is in all its glory.

Pretty wild how one item can stall an entire project. Onwards. We’re going through mechanical and inspections this week (electrical already passed), and then on to health, fire, and building next week. If all goes as planned (hah!) we’ll be able to start actually butchering and cooking late next week 🎉 And then….grand opening.

This newsletter will be first to hear when we pick a grand opening date. That update should come soon (learned my lesson about being too specific…)

Sourcing

Although construction was a huge focus for January, we made continued progress on research and sourcing too.

Hopefully readers have liked our research essays on the best nut butters, the best chicken, the best bread, and the cleanest food packaging materials. All of this research is directly applied to our sourcing practices. It’s a continuous process to learn, apply, learn, apply. Our products and practices will keep getting better and better, cleaner and cleaner, more and more nutritious.

Radius is a grocery store, yeah, but really it’s an applied research effort to prove what the American food system can be — clean, local, delicious, and nutritious. Our marketing strategy is to research, do the right thing, and then tell people about it. Here are some highlights of applied research from January.

Chicken research essay

We’ve spent the last 6 months researching chicken. Chicken is the most consumed meat in the United States, yet most Americans don’t know much about what they’re eating. While many consumers can debate the merits of grass-fed vs grain-fed beef and distinguish between Angus and Wagyu breeds, few can compare Cornish Cross vs Color Yield chicken breeds or explain the pros and cons of soy-free feed.

Most grocery store chicken is a Cornish Cross breed raised in an indoor warehouse on a diet of conventional GMO feed of corn, soy, and wheat. These birds are harvested at 5 weeks, and if they weren’t harvested at that age they wouldn’t be healthy enough to live past it. Their legs are not strong enough to support their breast-heavy body composition, and they drag their feathers on the ground. It’s not good animal welfare, it’s not a healthy chicken, and it’s not a nutritious chicken to consume.

We can do better. That's why we partnered with Greener Pastures to raise a slow-growth breed (Pioneer) with better genetics, higher activity levels, and better flavor.

If you live in Central Texas and can shop at Radius, we hope our chicken guide helps you understand how we selected our chicken farms and the level of care we put into sourcing. If you don’t live nearby, we hope it helps find the most nutritious chicken near you. Read the full guide, or if you don’t want to read a 4,000 word research essay about chicken (shame!), here's a 2 minute video summary (with obligatory Seinfeld clip!).

Nut Butters research essay

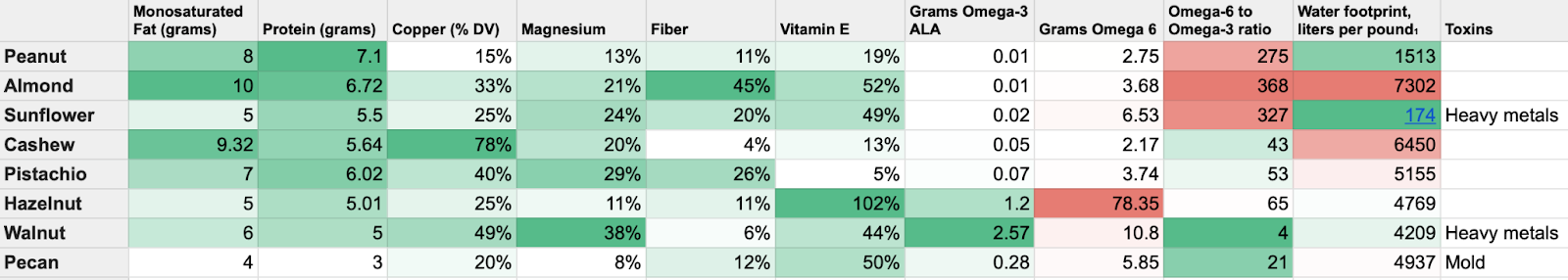

What nut butter reigns supreme when it comes to environmental footprint and nutritional profile? Turns out, the humble peanut.

While we hate to disappoint fans of the many exotic and interesting new nut butters on the market, peanut is a classic for a reason. Let’s start with health. Peanut butter is highest on the protein scale, with respectable levels of copper and magnesium, a not terrible Omega 6 to 3 ratio, minimal toxin concerns, and a reasonable amount of fiber. However, it’s from an environmental and ethical perspective that the humble peanut truly shines. Not only is it one of the most sustainable, water friendly, and soil regenerative nut butter options, peanuts are also commonly grown in the USA, so you can easily find one with a more minimal carbon footprint and shorter shipping distance.

Here’s our nut butter analysis in one image:

Bread research essay

Our bread and flour research started with a simple question — why is bread so much better in Europe? Why does it taste better, and why is it easier to digest? The closer we looked, the more differences we found between American and European bread, wheat, and gluten. Here are the factors to consider:

- Wheat varieties and gluten levels: European bakers often use wheat varieties with lower gluten levels that are easier to digest.

- Glyphosate: Glyphosate is banned in many European countries, and unfortunately common in the U.S. at multiple stages of wheat’s lifecycle.

- Additives during harvest, storage, and baking: Like glyphosate, Europe bans many chemical additives that are common in the U.S.

- Fermentation and baking process: Sourdough fermentation and high heat baking are two more factors that make flour products more digestible.

We want our flour and flour products to be the best you can find in America. Starting with flour, we believe Barton Springs Mill has a product that's as close as you can get to EU flour in America—maybe even better, in our opinion! BSM uses heirloom grains raised with organic practices and no chemical storing agents. They work directly with all their farmers and mill the flour on site in big stone mills.

Our fresh baked breads will be made by Texas French Bread who combine the highest standards of European baking techniques with a commitment to locally sourced flour. Their bread is made from a blend of Barton Springs Mill and Central Milling organic flour, and since 1981, they’ve been creating breads without any of the suspicious additives, high sugar, or other concerning ingredients and processes that make American breads so difficult to digest.

We also collaborated with Matok Bakery to create a 100% Barton Springs Mill heirloom grain challah that we'll offer every Friday.

Plastic research essay

While many consumers are aware of the negative health and environmental effects of plastic, there is confusion about new packaging types that are supposedly better for us and the planet. BPA-free plastic is safe right? And compostable plastic is even better? What about paper packaging? Are these actually better for human health and the environment? Sadly, based on our packaging research, the answer is no.

When you assess all the food packaging options, glass is the clear winner. This old school material may not be as flexible or light as plastic, but its nonreactive nature means that it safely contains food without leaching harmful compounds into our environments or bodies. We’re doing as much as possible to eliminate plastic from Radius. A few examples:

- All of our in-house items (stocks, pates, dips, etc) will be packaged in glass containers.

- We will not use any plastic cutting boards, only wood and rubber wood.

- We will use unlined butcher paper instead of coated paper.

- Where possible, we will source CPG items that are plastic free. Condiments in glass bottles, teas in unbleached and plastic free bags, produce without plastic packaging.

- We will use stainless steel produce sprayers. If by some miracle produce gets to us without any plastic residue, it would be a true shame to spray it with water coming from plastic containers or through plastic tubing (like every single grocery store in America does today).

Seed Oils

If partnering with a local farm to raise a better breed of chicken, researching the nutritional and environmental differences of nut butter, collaborating with a local baker to create an heirloom grain challah, AND working to eliminate plastic from back of house production and front of house packing isn’t enough work for one month, then we have one more thing that we’ve been working on for many months.

Radius will be first and only grocery store to be completely seed oil free. No seed oils are used in any of the items we make in house or any of the packaged items we sourced. This took a shocking (and depressing) amount of effort to eliminate seed oils! We’re proud to be the first.

Conclusion

In conclusion, we care. Intensely. We care about construction details to build the most beautiful grocery shopping experience possible. We care about sourcing efforts to find or create the cleanest, tastiest, most nutritious food. And this is just the beginning. We will continue to research and push the boundaries of what the American food system can be to bring you the best grocery store in America.

Coming Soon :)